Quality comes before quantity – but we provide you with both.

We have four different types of bonds in our current range of products. We are constantly working on

new qualities to advance our products and meet the steadily growing demands of our customers.

EPOXY RESIN

Epoxy resin-bonded abrasives are made of resin, a curing agent and the abrasive grain. These abrasives are also cast like magnesite-bonded grinding stones. The advantages of this bond are as follows: unlike magnesite-bonded grinding stones which can only reach a maximum operating speed of 20m/s, once approved, an epoxy resin abrasive can reach an operating speed of up to 50m/s and over.

In addition, when using epoxy resin-bonded abrasives, the machine parts do not corrode as there is no magnesium chloride in these abrasives.

We can create an abrasive customised to your requirements upon request, and also as 2-zone variants with an exterior diameter of up to 710 mm.

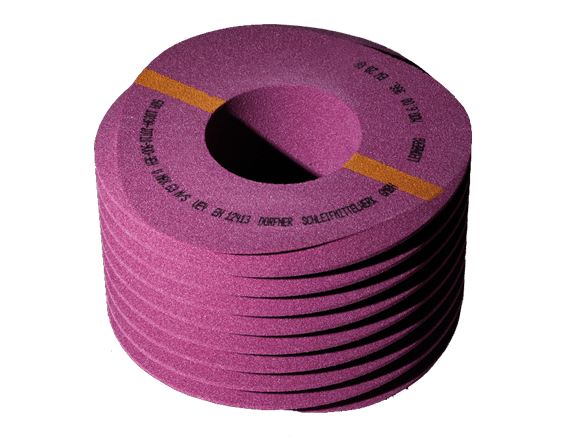

ARTIFICIAL RESIN

In resin-bonded abrasives, the abrasive grain is covered with a film of resin. Unlike ceramic-bonded abrasives, these abrasives are slightly elastic due to the properties of the resin, and are therefore less sensitive to shock.

This elasticity means this kind of bond is particularly suitable for polishing and fine grinding work.

Rough and dry grinding is also possible. We manufacture these varieties of abrasive with an exterior diameter of up to 1000mm as well as segments in all of the commonly used dimensions.

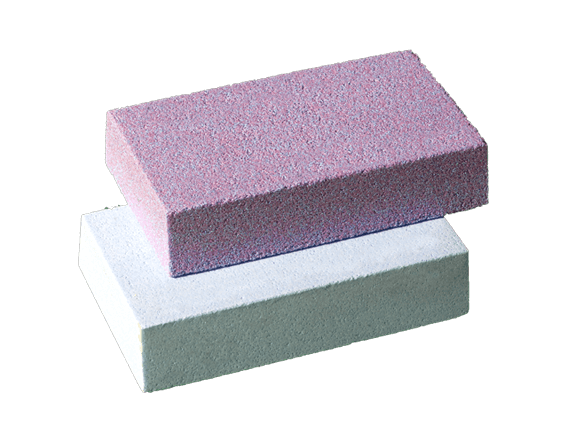

CERAMIC

Ceramic-bonded abrasives are mainly used for precision grinding. The bond is made of high-quality natural and artificial mineral raw materials.

This kind of bond is not sensitive to chemical exposure and can be stored indefinitely.

Since ceramic-bonded abrasives are less elastic, more rigid and brittle, even small shocks should be avoided at all costs. In Wuppertal, we manufacture ceramic-bonded grinding wheels as pressed products with an exterior diameter of up to 900mm and segments in all of the commonly used dimensions.

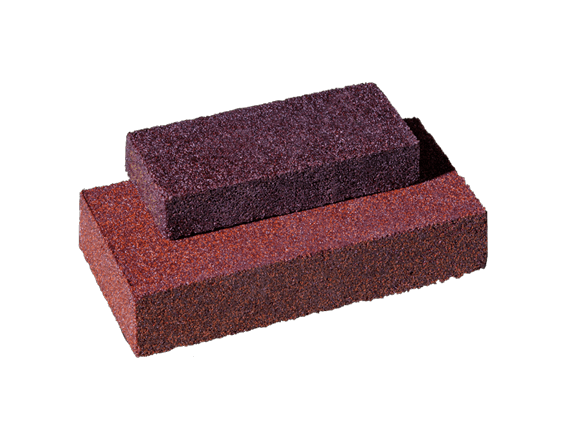

Magnesite

Abrasives with a magnesite bond are cast. They are therefore practically non-porous. Despite the absence of any gash volume, they are able to achieve a high rate of material removal in combination with an extremely cool cut, especially with hardened steel. To attain this rate of material removal, magnesite-bonded abrasives must be stored in a dry place for at least 6 weeks.

We manufacture magnesite-bonded abrasives with an exterior diameter of up to 2000mm.

To avoid long delivery times, we recommend make-and-take orders.

Do you have any questions about our products or require further information? Then please contact us via telephone, email or the contact form.